Been working on the design of the main mechanism of the joystick, partially based on Rob’s design but I realized I can’t mimic his completely because I’m also doing twist axis on the joystick which he doesn’t have (he uses pedals instead) adding twist complicates matters a fair bit since I can’t just clamp a metal pipe in the main gimbal mechanism anymore, I need an axle in the mix, and I can’t route cables down a pipe’s middle anymore either. Looked around at internal pictures of existing commercial joysticks to get ideas for my design and I’ve been shocked at how cheap and thin the mechanisms are, thin flimsy plastic with no bearings to speak of, just plastic pegs in plastic holes with grease, but I did spot an element I like in my Logitech “Extreme 3d Pro” it has a centering spring that works a lot like the x55 one except it’s reversed, the spring is attached to the bottom of the base and as the stick moves it angled down onto a plate attached to the spring, nifty design that doesn’t require the joystick’s base’s top to be structural. Also contained a nice spring in it’s twist mechanism I can re-use for the same purpose, also had a very nice digital hat design I’ll make use of, picture a square peg in a square hole with some extra room to let the peg shift in 4 directions a small amount but not not rotate, hole and pin extend into a cone like shape and at the top of the cone of the peg is a concave rubber clad thing for you to rest your thumb in, there are 4 tactile buttons near the top of the cone inside, as you move the rubber piece u/d/l/r you activate one of the 4 switches.

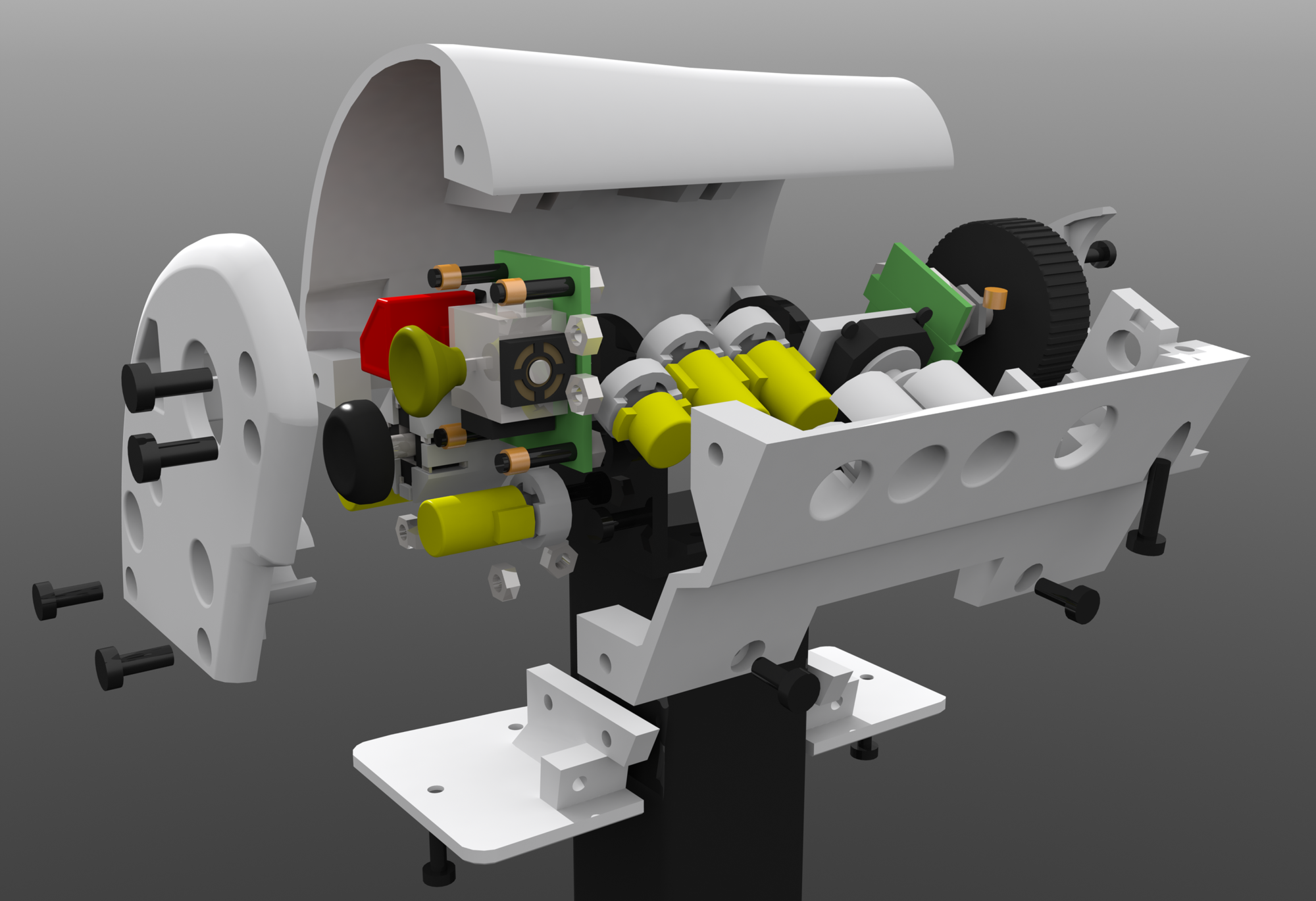

Here is the design currently:

Working on the pitch axis bolt design, need to look for suitable M8 bolts, ones I’ve found so far in the bins are all threaded only half way, which doesn’t work in this application, I need a nut fairly close to the head end, I originally wanted to put the head inside the blue piece but that doesn’t really work, can’t assemble it like that. One of those problems you need to keep in mind when designing something like this, it has to come together, if one step blocks another later in the sequence it doesn’t work. Yaw axis can use the head inwards because without the pitch axis installed there is ample room to push them in in that orientation, not an option for pitch.

Blocking out the main mechanism for now, I’ll add the centering spring and all the holes/divots and brackets to hold the potentiometers and later hall effect sensors and magnets to actually read the stick’s angle later.