Been working on the model further, version 1 of pretty much all of it nailed down:

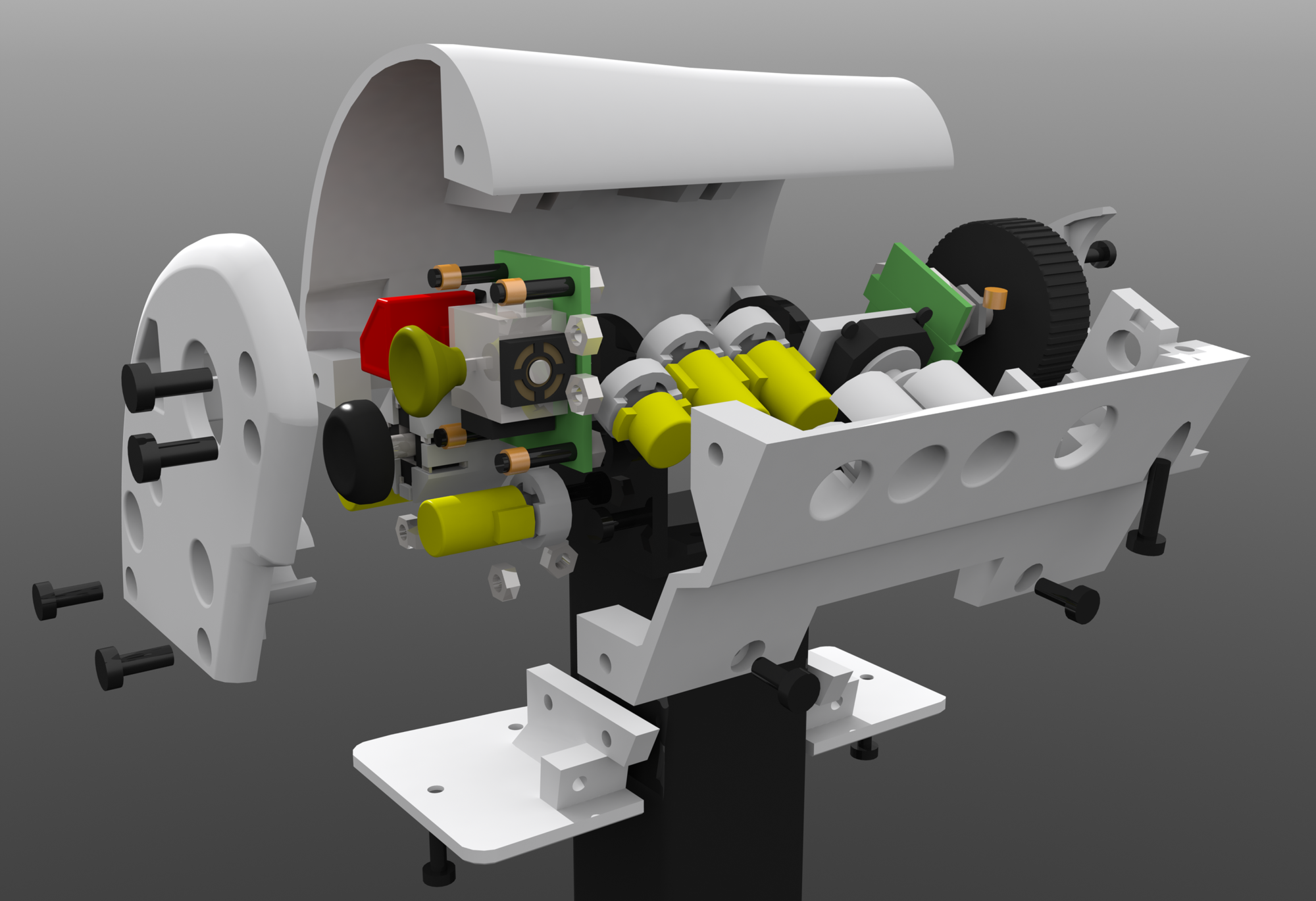

Exploded view showing the complexity of the design, it’s very dense in there and assembly requires a particular order for it all to come together.

Whole design as it stands in the correct colors.

Handrest piece, printed with supports was the trickiest piece to print since it’s so large and fairly thin, ABS shrinks when it cools which can cause warping, making the print come of the bed or get away from the hotend creating cracks.

I got some minor cracks but the one benefit of ABS is that it dissolves in acetone, mix some failed/retired prints with acetone (in a sealed container preferably) and you have “ABS juice” which you can use to mend cracks, glue 2 parts together etc.

Other panels, buttons and rotary encoder knob were easier to print, there is some post processing left particularly on the front where a support was detached, a lot of sanding to do, later priming, painting and clear-coat but I’ll do that only if I don’t want to change something after trying it.

It feels extremely solid when it’s all screwed together, I push pull and twist on it and it doesn’t budge, feels like a solid lump of plastic.

Next step is wiring, sadly even the low amount of buttons and axis I got currently is more than my Pro micro supports:

Encoder: 2 pins (interrupts)

Digital hat: 4 pins

6 buttons: 6 pins

Thumbstick: 2 analog pins + 1 digital pin (push)

PSP Thumbstick: 2 analog pins

Throttle: 1 analog pin

2+4+6+1=13 digital pins

2+1+2=5 analog pins

My Pro micro has 4 analog pins and 12 digital pins, and I’m adding more buttons, knobs etc to the base. I think the solution is to instead of going one arduino use multiple and network them:

Pro micro and 2x pro minis, very similar boards but require an external FTDI programmer (which I got) and doesn’t have native USB support, benefit of them is that they’re much cheaper because of those limitations, using a network of arduino also has the benefit of not having to run a massive amount of wires from the throttle’s handle to the throttle’s base, without this solution I’d have to run minimum 13+4=17 wires + 5v and ground, with a network I just need 2 wires + 5v and ground.

Very nice work (6 years later)! Just starting to tread down the same path myself, your method of the spring for zeroing it out I like and will probably borrow myself. Would love to hear if anything else interesting ever came of this project, any useful tips or anything. Will be sure to read through the rest of the posts!